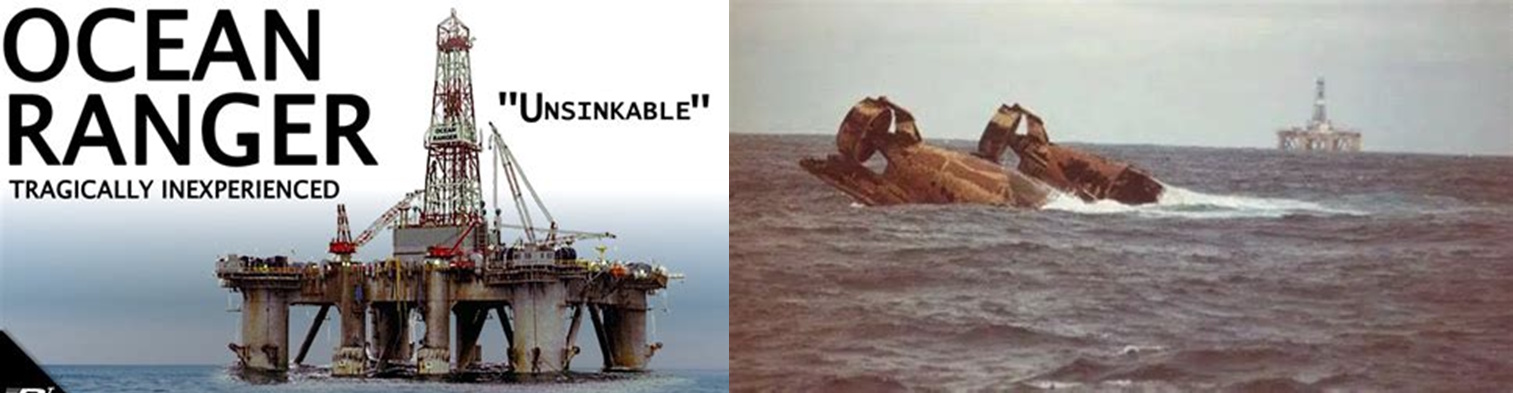

February 15, 1982, 1:30 AM. The semi-submersible drilling platform Ocean Ranger battled 100-foot waves and hurricane-force winds in the North Atlantic, 175 miles southeast of Newfoundland. Within hours, the platform would sink taking all 84 crew members to their deaths in one of the worst offshore disasters in history.

While the immediate cause involved ballast control system failure, the disaster highlighted fundamental weaknesses in offshore lifting and structural systems that had evolved without comprehensive standards for the harsh marine environment. The tragedy exposed how seemingly minor design details—like padeye connections, lifting points, and emergency equipment attachments—could mean the difference between life and death when offshore platforms face extreme weather conditions.

The Ocean Ranger catastrophe demonstrated that offshore structures require lifting and connection systems designed to standards far exceeding those used onshore. The combination of dynamic loading from waves, corrosive saltwater environment, and limited rescue capabilities creates demands that conventional design approaches cannot adequately address, driving the development of specialized standards like API RP 2A.

P_working = SWL / SF

This basic safe working load relationship—where SWL represents safe working load and SF denotes safety factor—governed traditional lifting equipment design. But offshore applications revealed that simple static safety factors proved inadequate when dynamic amplification, environmental degradation, and emergency loading conditions combined to create forces far exceeding conventional design assumptions.

The Engineering Foundation: Understanding API Standards for Marine Lifting

The Engineering Foundation: Understanding API Standards for Marine Lifting

The American Petroleum Institute's development of offshore design standards represents one of the most comprehensive responses to the unique engineering challenges posed by marine environments. API standards for padeye design and lifting equipment evolved from decades of offshore experience where conventional land-based methods proved inadequate for the harsh realities of oil and gas operations.

Padeyes—the robust steel attachment points used throughout offshore platforms—must withstand not only planned lifting operations but also emergency loads, storm conditions, and the relentless corrosive assault of saltwater spray. Unlike simple lifting lugs, padeyes incorporate sophisticated design features that account for multi-directional loading, fatigue from wave action, and the possibility of overload during emergency operations.

The fundamental challenge in offshore padeye design lies in accommodating the complex loading conditions that develop during marine lifting operations. Traditional lifting assumes controlled conditions with known load directions, but offshore operations involve vessel motion, wind forces, and wave-induced dynamics that create constantly changing load vectors and magnitudes.

F_dynamic = F_static × DAF × (1 + α_motion + β_wind)

This dynamic force relationship demonstrates how static lifting loads F_static get amplified by dynamic amplification factors (DAF) and additional components from vessel motion α_motion and wind effects β_wind, creating total forces that can exceed static calculations by factors of 3.0 or more.

API standards address these challenges through comprehensive design methodologies that consider ultimate strength, fatigue life, and emergency loading scenarios. The standards recognize that offshore padeyes may experience millions of load cycles from wave action and vessel motion, requiring fatigue analysis approaches that land-based lifting equipment rarely needs.

N_cycles = f_wave × t_service × 365 × 24 × 3600

Where N_cycles represents the total fatigue cycles, f_wave is the wave frequency, and t_service denotes the service life in years. This relationship shows how seemingly innocuous wave motion creates fatigue loading that accumulates to millions of cycles over a platform's operational life.

The API approach also emphasizes redundancy and fail-safe design principles that recognize the consequences of lifting equipment failure in offshore environments. Unlike onshore operations where equipment failure might cause delays or property damage, offshore lifting failures can directly threaten human life by compromising evacuation systems or emergency response capabilities.

RF = min[P_primary, P_backup] / P_required

This redundancy factor RF ensures that even if primary load paths fail, backup systems maintain adequate capacity P_backup to handle required loads P_required, providing the multiple levels of protection essential for offshore safety.

Real-World Applications: Where API Standards Save Lives at Sea

Real-World Applications: Where API Standards Save Lives at Sea

API padeye design standards have become indispensable across the offshore industry, where lifting operations occur under conditions that would be considered impossible for land-based construction. From routine supply operations to emergency evacuations, these robust connection points must perform flawlessly when lives depend on their reliability.

Offshore platform construction relies heavily on API-compliant padeyes for installing massive structural components weighing hundreds of tons. Jacket legs, deck modules, and drilling equipment all require lifting points capable of handling extreme loads while resisting the corrosive marine environment throughout decades of service life.

Supply vessel operations subject padeyes to some of the most demanding service conditions imaginable. Cargo transfers in rough seas create dynamic loading that can amplify static loads by 300% or more, while salt spray and temperature cycling attack the metallurgy. Emergency towing connections must function reliably even after years of exposure to marine conditions.

Our repository's API PADEYE Design calculation (downloaded over 1,380 times with a 4.1-star rating), developed by community contributors, addresses these complex design scenarios through comprehensive implementation of API RP 2A requirements for ultimate strength, fatigue analysis, and environmental considerations.

Drilling operations demand padeyes capable of supporting critical equipment under extreme conditions. Blowout preventer lifting points, riser tensioning systems, and emergency disconnect mechanisms all rely on API-compliant connections that must function reliably when conventional lifting equipment would fail catastrophically.

Floating production systems present unique challenges where padeyes must accommodate not only planned lifting operations but also emergency scenarios involving weather routing, collision avoidance, and system shutdown procedures. The dynamic positioning systems that maintain station-keeping create additional loading patterns that static analysis cannot predict.

Subsea operations push API padeye design to its limits with applications involving deep water, high pressure, and remotely operated vehicles. Subsea manifold lifting points, pipeline connection hardware, and emergency recovery systems all require the sophisticated design approaches that API standards provide.

The Padeye Design calculation (376 downloads, 4.1-star rating) demonstrates general marine applications, while Padeye and sling calculations with or without gussets (260 downloads, 4.6-star rating) addresses structural integration considerations essential for offshore applications.

The Hidden Complexity: Why Offshore Lifting Defies Simple Analysis

The Hidden Complexity: Why Offshore Lifting Defies Simple Analysis

The apparent simplicity of padeye connections conceals extraordinary engineering complexity that emerges from the unique combination of marine environment, dynamic loading, and critical safety requirements that define offshore operations. What appears as a straightforward steel attachment point actually requires sophisticated analysis of multiple interacting phenomena that simple calculations cannot capture.

Wave-induced vessel motion creates dynamic loading patterns that challenge every assumption underlying conventional lifting analysis. Heave, pitch, and roll motions combine to produce constantly changing load directions and magnitudes that can amplify static forces by factors exceeding 5.0 during storm conditions, making accurate dynamic analysis essential for safe design.

F_resultant = √[(F_x + ΔF_heave)² + (F_y + ΔF_pitch)² + (F_z + ΔF_roll)²]

This resultant force relationship demonstrates how vessel motions ΔF_heave, ΔF_pitch, and ΔF_roll combine with static load components to create total forces that exceed simple vector addition, requiring sophisticated analysis methods to predict accurately.

Corrosion mechanisms in marine environments attack padeye connections through multiple pathways that interact in complex ways. Uniform corrosion reduces section properties predictably, but pitting corrosion and stress corrosion cracking create localized failures that can occur without visible warning signs, making material selection and protection systems critical design considerations.

While these equations look intimidating on paper, our XLC add-in displays them as easily readable mathematical equations directly in Excel, transforming the complex requirements of API standards into practical design tools that engineers can confidently apply without requiring specialized offshore engineering software or extensive marine experience.

Fatigue loading from wave action creates stress cycles that accumulate over millions of repetitions throughout a platform's service life. Unlike onshore lifting equipment that experiences occasional use, offshore padeyes endure continuous cyclic loading that requires fatigue analysis approaches specifically developed for marine applications.

Δσ_effective = K_f × Δσ_nominal × SCF_marine

Where Δσ_effective represents the effective stress range, K_f accounts for fatigue concentration effects, and SCF_marine includes marine-specific stress concentration factors that account for corrosion, weld quality, and dynamic amplification effects unique to offshore environments.

Emergency loading scenarios introduce additional complexity that defies conventional analysis approaches. During platform evacuation or emergency response operations, padeyes may experience loads far exceeding design values as personnel use any available attachment point for escape or rescue operations, requiring design margins that account for human behavior under extreme stress.

Multi-directional loading effects create stress combinations that simple uniaxial analysis cannot predict. Offshore lifting operations rarely involve purely vertical loads, instead creating complex three-dimensional stress states that require sophisticated analysis methods to ensure adequate safety margins in all loading directions.

Professional Approach: Implementing API Standards for Offshore Reliability

Professional Approach: Implementing API Standards for Offshore Reliability

The critical nature of offshore padeye applications demands rigorous professional practices that extend far beyond simple strength calculations to encompass fatigue analysis, environmental considerations, and emergency loading scenarios that reflect the unique challenges of marine operations where equipment failure can directly threaten human life.

The ExcelCalcs community shares a passion for making accurate calculations with MS Excel, providing a platform where engineers can access expert knowledge through our comments feature and benefit from collective experience with API standards across diverse offshore applications from drilling platforms to floating production systems.

Professional API implementation begins with comprehensive hazard identification that considers all potential loading scenarios including normal operations, storm conditions, emergency situations, and equipment malfunction events. Each scenario requires independent analysis using API methodologies, with the governing case determining design adequacy regardless of margins in other loading conditions.

Environmental assessment becomes critical given the aggressive marine conditions that affect material properties, corrosion rates, and fatigue performance throughout the padeye's service life. Temperature cycling, salt spray exposure, and cathodic protection systems all influence design requirements in ways that require careful consideration during the design phase.

Our repository's worked solutions give engineers a head start in implementing API's sophisticated design requirements while building on existing Excel skills with a much faster learning curve than specialized offshore engineering software that requires extensive training and annual licensing costs often exceeding tens of thousands of dollars.

Quality assurance procedures for offshore padeyes must address manufacturing standards, material certifications, and installation requirements that ensure design assumptions remain valid throughout construction and installation. Weld quality, material traceability, and dimensional tolerances all affect padeye performance in ways that require rigorous specification and verification.

Inspection and maintenance programs become essential given the harsh marine environment and critical safety functions that padeyes serve. Non-destructive testing requirements, corrosion monitoring, and service life assessment all require specialized expertise and equipment designed for offshore conditions.

Risk assessment methodologies help prioritize design effort and inspection resources by identifying the padeyes with highest consequence of failure and greatest exposure to degradation mechanisms. Quality assurance through comments feature and peer review helps ensure that risk assessments address the most critical failure modes while maintaining practical implementation approaches.

Repository Showcase: Comprehensive API and Marine Lifting Solutions

Repository Showcase: Comprehensive API and Marine Lifting Solutions

Beyond our flagship API PADEYE Design analysis, engineers can access specialized calculations including Padeye Design (376 downloads, 4.1-star rating), Offshore Tubular Joints Punch Check as per API-WSD (138 downloads, 4.5-star rating), and Check of Tubular Members as per API RP2A - LFRD Code for offshore structural applications (103 downloads, 4.8-star rating).

For specialized lifting applications, our repository includes Padeye and sling calculations with or without gussets (260 downloads, 4.6-star rating), Spreader Bar Lifting Device Calculations and Design for heavy lift operations (420 downloads, 4.4-star rating), and Tension in Lifting Slings (203 downloads, 4.1-star rating). Marine practitioners can utilize API 650 - Optimized Preliminary Tank Calculation for storage tank applications (406 downloads, 3.9-star rating), while offshore engineers can access API-650 designed for comprehensive tank analysis (410 downloads, 4.2-star rating). International applications are supported through Lifting Lug BS EN 1993-1-8 for European offshore standards (32 downloads, 4.7-star rating). This diversity ensures that regardless of your offshore application or specific API standard requirements, our community has developed comprehensive solutions to meet your marine engineering needs.

Advanced crane and lifting analysis tools include Crane Design Guide to BS 5950 for structural applications (667 downloads, 4.3-star rating), Kroll K25000 Tower Crane for specific equipment analysis (172 downloads, 4.9-star rating), and Tension in slings with soft top loop for rigging applications (62 downloads, 5.0-star rating). The comprehensive nature of our marine and API standards library reflects decades of collective offshore engineering experience across drilling, production, and marine construction applications.

Start Your API Offshore Design Journey Today

Start Your API Offshore Design Journey Today

The demanding nature of offshore operations requires padeye design tools that incorporate API standards while remaining accessible to practicing engineers. Our API PADEYE Design calculation represents the culmination of extensive community development, incorporating ultimate strength, fatigue analysis, and environmental considerations into a comprehensive design tool that handles the complexity of offshore marine applications.

We extend our appreciation to the engineering contributors who developed these essential calculation tools, transforming the sophisticated requirements of API standards into practical design solutions that serve offshore engineers worldwide. Their expertise has created calculation templates that continue to evolve with industry advances and incorporate lessons learned from both successful offshore operations and documented failures.

Join the ExcelCalcs community with a $99 professional subscription—insignificant compared to MathCAD, Mathematica, or Maple—and gain access to our complete repository of API and marine engineering solutions. Students and educators benefit from our 50% academic discount, while free trials allow you to explore the comprehensive capabilities of our offshore design calculation tools without commitment.

Join the ExcelCalcs community today and discover why thousands of engineers trust our templates for their most critical offshore design challenges. Because when padeyes must perform reliably in the harsh marine environment where lives depend on their integrity, you need calculations that understand the sophisticated engineering behind API standards.