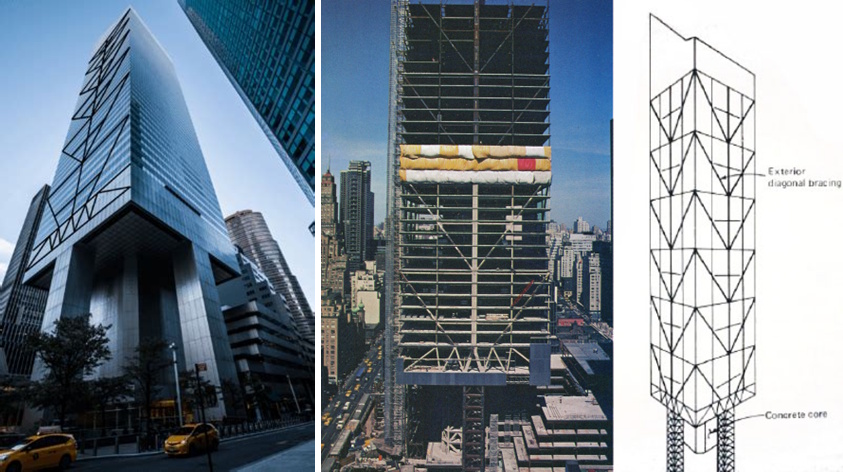

July 1978. Fifty-nine stories above Manhattan, structural engineer William LeMessurier faced every engineer's worst nightmare. His calculations revealed that the Citicorp Center—the world's seventh-tallest skyscraper—could collapse in a 70-mph wind. Hurricane season was approaching, and the building was occupied by thousands of people completely unaware of the danger above their heads.

The crisis began with what seemed like a routine design change: to save money, the steel contractor had substituted bolted connections for the originally specified welded joints in the building's diagonal wind braces. LeMessurier's office had approved the change using simple static calculations that showed the bolted connections could handle the required loads. But these calculations missed a critical factor: quartering winds hitting the building diagonally created a 160% increase in bolt forces that the simple analysis couldn't capture.

The Citicorp Center disaster-that-never-was demonstrates the fundamental challenge in bolt calculations: the difference between what simple math suggests is adequate and what complex failure mechanisms reveal about actual structural behavior. While basic load calculations showed the bolts were strong enough, they failed to account for the dynamic amplification effects and load redistribution that made the connections dangerously inadequate under realistic wind conditions.

F_simple = P / n_bolts

This elementary relationship—force equals load divided by number of bolts—governed the Citicorp Center connection analysis and continues to provide accurate results for the majority of engineering applications. The Citicorp crisis demonstrates what happens when engineers apply this oversimplification to complex situations without considering the dynamic effects and load redistribution that simple static calculations cannot capture.

The Engineering Foundation: Understanding the Spectrum of Bolt Analysis

The Engineering Foundation: Understanding the Spectrum of Bolt Analysis

The evolution of bolt calculation methods reflects the broader development of structural engineering from empirical rules to sophisticated theoretical analysis. Modern engineers must navigate this spectrum intelligently, selecting analysis approaches that match the complexity of their applications while avoiding both dangerous oversimplification and wasteful over-analysis.

Simple bolt calculations assume uniform load distribution among all bolts in a connection, with each bolt carrying an equal share of the applied loads. This assumption works remarkably well for many applications, particularly when bolt groups are arranged symmetrically and loads apply through the connection's centroid without significant eccentricity or rotation.

f_v = V / (n × A_b)

f_t = T / (n × A_b)

These fundamental stress relationships define shear and tension stresses in terms of applied loads V and T, number of bolts n, and bolt area A_b. For countless applications, these simple formulas provide adequate accuracy while enabling rapid design iterations and clear engineering communication.

The transition from simple to complex analysis becomes necessary when basic assumptions break down. Eccentric loading, non-uniform bolt patterns, combined loading conditions, and dynamic effects all create situations where simple load division fails to predict actual bolt behavior with sufficient accuracy for safe design.

Complex bolt analysis recognizes that real connections exhibit sophisticated load-sharing behavior that depends on connection stiffness, bolt-to-hole clearances, material properties, and geometric arrangements. These factors create non-uniform stress distributions that can cause some bolts to reach capacity while others remain lightly loaded.

f_i = f_direct + f_eccentric = P/n + (M × r_i × cos θ_i) / Σ(r_i²)

This elastic analysis relationship demonstrates how eccentric loading creates additional stresses that vary with each bolt's distance r_i from the connection centroid. The resulting stress distribution often differs dramatically from simple uniform assumptions, potentially causing unexpected failures in connections that appear adequately designed using basic methods.

The challenge for practicing engineers lies in recognizing when to transition between analysis approaches. Simple methods remain appropriate for routine connections with symmetric loading, while complex analysis becomes essential for critical connections, unusual geometries, or demanding service conditions.

Real-World Applications: Where Simple and Complex Methods Define Practice

Real-World Applications: Where Simple and Complex Methods Define Practice

The choice between simple and complex bolt analysis methods profoundly influences engineering practice across all scales of construction, from routine structural details to complex industrial installations. Understanding when each approach provides appropriate accuracy enables engineers to optimize both safety and efficiency while maintaining practical design workflows.

Routine building construction relies heavily on simple bolt calculations for standard connections that appear repeatedly throughout typical projects. Beam-to-column shear connections, bracing attachments, and secondary member connections often involve symmetric loading conditions where simple analysis provides adequate accuracy while enabling rapid design iteration and economical detailing.

Industrial applications frequently demand complex analysis approaches given the unusual loading conditions, critical service requirements, and high consequence of failure typical in process facilities. Equipment connections, pressure vessel supports, and dynamic machinery foundations often involve eccentric loading, vibration effects, and fatigue considerations that simple methods cannot adequately address.

Our repository's SimpleBoltCalc.xls calculation (downloaded over 1,302 times with a 3.9-star rating), developed by community contributors, demonstrates the power of straightforward analysis approaches for applications where basic assumptions remain valid and complex methods add unnecessary complication without improving accuracy.

Bridge construction showcases the full spectrum from simple to complex bolt analysis within single projects. Standard splice connections in non-critical members often utilize simple methods successfully, while main load-path connections require sophisticated analysis that accounts for fatigue loading, dynamic amplification, and progressive failure scenarios that could affect structural system integrity.

Seismic design applications highlight the critical importance of selecting appropriate analysis complexity. Simple bolt calculations often provide adequate accuracy for connections that remain elastic during earthquake loading, while connections expected to yield or undergo large deformations require complex analysis that accounts for cyclic loading effects and connection flexibility.

Retrofit and strengthening projects frequently encounter situations where existing connections were designed using simple methods that no longer meet current code requirements. Engineers must evaluate whether complex analysis can demonstrate adequate capacity in existing connections or whether physical strengthening becomes necessary to meet modern standards.

The Quick and Dirty Bolt Sizing Calculation.xls (678 downloads, 4.4-star rating) exemplifies the engineering value of rapid preliminary analysis that enables concept evaluation and initial sizing without the overhead of sophisticated modeling that may prove unnecessary for final design.

The Hidden Complexity: When Simple Methods Become Dangerous Simplifications

The Hidden Complexity: When Simple Methods Become Dangerous Simplifications

The seductive appeal of simple bolt calculations lies in their apparent clarity and ease of application, yet this simplicity can mask critical failure mechanisms that only emerge under complex analysis or real-world loading conditions. Recognizing the boundaries of simple method validity becomes essential for avoiding dangerous under-design while preventing unnecessary over-analysis.

Eccentric loading represents the most common situation where simple methods produce unconservative results. When loads apply away from connection centroids, bolt forces amplify significantly compared to simple load division, with the most distant bolts experiencing stress levels that can exceed capacity even when average stresses appear acceptable.

M_eccentric = P × e_distance

f_max = P/n + M_eccentric × r_max / Σ(r_i²)

These relationships demonstrate how load eccentricity e_distance creates moments that distribute unevenly among connection bolts, with maximum forces often exceeding simple calculations by factors of 2.0 or more. The stress amplification depends critically on bolt arrangement geometry and cannot be captured through simple uniform stress assumptions.

Connection flexibility introduces another layer of complexity that simple methods ignore. Real bolted connections exhibit load-deformation behavior that depends on bolt pretension, surface conditions, and hole tolerances. This flexibility affects load distribution among bolts and can cause progressive failure modes that simple elastic analysis cannot predict.

While these equations look intimidating on paper, our XLC add-in displays them as easily readable mathematical equations directly in Excel, transforming complex bolt analysis relationships into practical design tools that engineers can apply without specialized training or expensive finite element software packages.

Dynamic loading effects present situations where simple static analysis becomes inadequate regardless of safety factors applied. Vibrating machinery, impact loads, and fatigue conditions create stress amplifications and failure mechanisms that static calculations cannot capture, requiring specialized dynamic analysis approaches for reliable design.

σ_dynamic = DAF × σ_static

Dynamic amplification factors (DAF) can range from 1.5 for controlled loading to 3.0 or higher for impact conditions, making simple static calculations dangerously unconservative for dynamic applications. The amplification depends on loading frequency, structural damping, and connection details in ways that require sophisticated analysis for accurate prediction.

Material nonlinearity adds complexity that challenges even sophisticated analysis methods. As bolt connections approach capacity, yielding and bearing deformations create load redistributions that alter the fundamental assumptions underlying both simple and complex elastic analysis approaches. Understanding these limitations becomes critical for applications approaching ultimate capacity.

Group action effects in large bolt patterns create behavior that defies simple superposition principles. Adjacent bolts interact through the connected material, creating stress concentrations and load redistributions that depend on the entire connection geometry rather than individual bolt characteristics. These effects require numerical analysis approaches for accurate evaluation.

Professional Approach: Mastering the Art of Analysis Selection

Professional Approach: Mastering the Art of Analysis Selection

The professional application of bolt calculations demands systematic approaches that balance analysis sophistication with practical engineering constraints. Successful engineers develop judgment regarding when simple methods provide adequate accuracy and when complex analysis becomes necessary for safety, reliability, or regulatory compliance.

The ExcelCalcs community shares a passion for making accurate calculations with MS Excel, providing a platform where engineers can access expert knowledge through our comments feature and benefit from collective experience with both simple and sophisticated bolt analysis approaches across diverse engineering applications.

Professional practice begins with systematic evaluation of connection characteristics that determine appropriate analysis complexity. Loading type, geometry constraints, material properties, and service conditions all influence whether simple assumptions remain valid or complex methods become necessary for reliable design outcomes.

Cost-benefit analysis guides the selection between simple and complex approaches by considering analysis time, software requirements, and potential consequences of under-design versus over-design. Simple methods often provide optimal efficiency for routine applications, while complex analysis becomes cost-effective for critical connections or unusual circumstances.

Our repository's worked solutions give engineers a head start in developing systematic approaches to analysis selection while building on existing Excel skills with a much faster learning curve than specialized finite element packages that require extensive training and annual licensing costs exceeding thousands of dollars.

Quality assurance procedures must align with the analysis approach selected. Simple calculations require verification of basic assumptions and load path clarity, while complex analysis demands additional checks of modeling assumptions, boundary conditions, and result interpretation that ensure sophisticated methods produce reliable outcomes.

Documentation standards vary with analysis complexity but must always communicate the assumptions underlying design decisions. Simple calculations require clear presentation of loads, bolt arrangements, and capacity checks, while complex analysis demands additional documentation of modeling approaches and sensitivity studies that demonstrate result reliability.

Professional development requires understanding both simple and complex methods along with their appropriate applications. Engineers who master this spectrum can optimize their approach for each project while maintaining confidence in their design decisions regardless of analysis sophistication employed.

Repository Showcase: Comprehensive Bolt Analysis Solutions Across the Complexity Spectrum

Repository Showcase: Comprehensive Bolt Analysis Solutions Across the Complexity Spectrum

Beyond our flagship SimpleBoltCalc analysis, engineers can access sophisticated calculations including Ultimate shear capacity of bolt group.xls (719 downloads, 5.0-star rating), BoltedJoint.xls (863 downloads, 4.4-star rating), and Detailed Bolted Joint Calculations for comprehensive analysis (790 downloads, 4.5-star rating).

For specialized applications, our repository includes Bolt Group Shear Calculation (386 downloads, 4.3-star rating), Eccentric Loaded Bolted Joint for complex loading scenarios (173 downloads, 3.8-star rating), and US Bolt Calculator (225 downloads, 4.7-star rating). Advanced practitioners can utilize Taki FE Spreadsheet 02 - bolted_joint_070506.xls for finite element verification (395 downloads, 3.0-star rating), while specialized applications can access Connecting Rod Bolts Calculation with VDI 2230 standards designed for automotive applications (69 downloads, 4.4-star rating). This diversity ensures that regardless of your analysis complexity requirements or specific application demands, our community has developed solutions spanning the full spectrum from simple to sophisticated approaches.

Practical design tools include BOLT DETAIL CALCS. for comprehensive documentation (257 downloads, 4.4-star rating), Bolt length calculator for practical detailing (52 downloads, 4.1-star rating), and Bolt torque/tension calc for installation verification (295 downloads, 3.8-star rating). The comprehensive nature of our bolt analysis library reflects decades of collective engineering experience with applications ranging from simple structural connections to sophisticated machine design.

Start Your Optimal Bolt Analysis Journey Today

Start Your Optimal Bolt Analysis Journey Today

The art of bolt calculations lies in selecting the analysis approach that matches your application's complexity while optimizing engineering efficiency and design reliability. Our SimpleBoltCalc.xls calculation represents the culmination of engineering wisdom regarding when straightforward methods provide adequate accuracy, while our comprehensive repository offers sophisticated alternatives when applications demand complex analysis approaches.

We extend our appreciation to the engineering contributors who developed these essential calculation tools, transforming both simple principles and complex theoretical relationships into practical design solutions that serve engineers across the full spectrum of bolt analysis applications. Their expertise has created calculation templates that help engineers select appropriate analysis sophistication for each unique situation.

Join the ExcelCalcs community with a $99 professional subscription—insignificant compared to MathCAD, Mathematica, or Maple—and gain access to our complete repository of bolt analysis solutions spanning simple to sophisticated approaches. Students and educators benefit from our 50% academic discount, while free trials allow you to explore the full range of calculation capabilities without commitment.

Join the ExcelCalcs community today and discover why thousands of engineers trust our templates for bolt calculations across the complexity spectrum. Because when connections must perform reliably and efficiently, you need calculations that understand the art of matching analysis sophistication to application requirements.