When Heavy Loads Meet Weak Soils: The Minnesota Warehouse Crisis

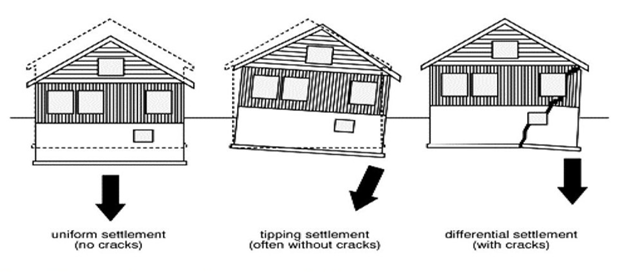

In 2022, a major distribution center in Minneapolis faced a costly crisis when differential settlement began plaguing their warehouse floor, creating operational nightmares and safety hazards. The 200,000-square-foot facility, designed to handle massive racking systems loaded with consumer goods, began showing signs of trouble within three years of construction. Workers reported difficulty operating forklifts as the floor developed uneven settlements of up to 3 inches in high-traffic areas, while automated storage systems experienced costly malfunctions due to rack misalignment caused by floor movement.

The investigation revealed a cascade of problems typical in ground-supported slab failures: inadequate soil preparation beneath the slab, non-uniform load patterns from concentrated racking systems, and insufficient consideration of soil-structure interaction. The warehouse's concrete slab, designed as a conventional 6-inch thick ground-supported system, had been adequate for the initial design loads but proved insufficient for the intense concentrated loading from modern high-density storage systems. The problem was compounded by Minnesota's challenging soil conditions—silty clay soils that expand dramatically when wet and shrink during dry periods, creating a constantly shifting foundation beneath the slab.

This failure exemplifies the fundamental challenge in ground-supported slab design: creating a structural system that can distribute concentrated loads effectively while accommodating the inevitable movements and settlements of the supporting soil. The basic principle governing slab-on-grade behavior involves the complex interaction between concrete flexural capacity and subgrade support.

Ground Slab Load Distribution = Applied Load ÷ Effective Contact Area

q = P / A_eff

Where q is the contact pressure on the subgrade, P is the applied load, and A_eff is the effective area of load distribution through the slab. Unlike elevated slabs that span between supports, ground-supported slabs derive their capacity from continuous contact with the soil, making soil properties critical to structural performance.

The Engineering Foundation: Understanding Slab-Soil Interaction

Ground-supported slabs represent a unique structural system where the concrete slab and supporting soil work together to resist applied loads. Unlike elevated slabs that function as conventional structural elements spanning between supports, slabs-on-grade derive their load-carrying capacity from continuous contact with the underlying soil, creating a complex interaction between structural engineering and geotechnical principles.

The fundamental behavior of ground-supported slabs involves load distribution through the concrete to the subgrade, with the slab acting as a load-distributing platform that spreads concentrated loads over larger soil areas. This mechanism allows relatively thin concrete slabs to support substantial loads by mobilizing the bearing capacity of the supporting soil over extended areas.

Subgrade Reaction Pressure = Modulus of Subgrade Reaction × Deflection

q = k × w

Where q is the soil reaction pressure, k is the modulus of subgrade reaction (typically 50-200 pci for common soils), and w is the slab deflection. This linear relationship, known as the Winkler foundation model, provides the basis for most slab-on-grade analysis despite its simplification of actual soil behavior.

The structural design of ground-supported slabs requires consideration of multiple loading scenarios: concentrated loads from equipment or storage systems, uniform loads from distributed storage, and the effects of shrinkage and temperature changes. Each loading condition creates different stress patterns in the slab, requiring comprehensive analysis to ensure adequate performance.

Maximum Bending Moment from Point Load = Load × Radius of Relative Stiffness

M_max = P × l / 4

Where P is the point load and l is the radius of relative stiffness, calculated as l = [E×t³/(12×(1-ν²)×k)]^0.25, where E is concrete modulus, t is slab thickness, ν is Poisson's ratio, and k is the subgrade modulus. This relationship demonstrates how slab thickness and soil stiffness interact to control load distribution and stress levels.

The interface between slab and soil presents additional complexities, as friction between these materials affects load transfer and movement accommodation. Temperature and shrinkage movements in the concrete must be accommodated without inducing excessive stresses, requiring careful consideration of joint spacing and reinforcement placement.

Real-World Applications: Where Ground-Supported Slabs Enable Commerce

Ground-supported slabs form the foundation of modern industrial and commercial operations, enabling the efficient movement and storage of goods that drive the global economy. From massive distribution centers that serve e-commerce networks to manufacturing facilities producing everything from automobiles to consumer electronics, these structural systems make possible the large, uninterrupted floor areas essential for modern industrial operations.

Warehouse and distribution facilities represent perhaps the most demanding applications for ground-supported slab design, where structures must support incredibly heavy and concentrated loads from high-density storage systems. Modern automated storage and retrieval systems can impose loads exceeding 1,000 pounds per square foot in concentrated areas, while the same facilities require smooth, level surfaces for efficient forklift and robotic operation.

Our repository's GRDSLAB.xls calculation (downloaded over 2,058 times with a 4.6-star rating), developed by community contributor Alex Tomanovich, addresses these complex design scenarios. This comprehensive tool analyzes ground-supported slabs for various loading conditions including point loads, line loads, and distributed loads while considering subgrade-slab interaction effects. The calculation provides detailed analysis of moments, shears, and deflections that engineers need for both structural adequacy and serviceability requirements.

Manufacturing facilities present unique ground-supported slab challenges where floors must accommodate not only static loads from equipment and materials but also dynamic forces from machinery operation, thermal effects from industrial processes, and chemical exposure from manufacturing operations. Heavy machinery such as stamping presses, rolling mills, and assembly line equipment can impose substantial concentrated loads while generating vibrations that must be controlled to maintain precision manufacturing tolerances.

Retail and commercial facilities require ground-supported slabs that provide smooth, durable surfaces capable of supporting customer traffic, merchandise displays, and material handling equipment while maintaining attractive appearance over decades of service. Big-box retail stores, shopping centers, and commercial buildings often feature large, uninterrupted floor areas that depend on properly designed ground-supported slabs for both structural performance and aesthetic appeal.

Cold storage and food processing facilities impose particularly demanding requirements on ground-supported slab design, where floors must resist freeze-thaw cycles, accommodate insulation systems, and provide chemical resistance while supporting heavy storage loads and specialized equipment. These applications often require specialized design considerations including sub-slab insulation, vapor barriers, and enhanced durability concrete mixes.

The Hidden Complexity: Why Simple Slab Design Becomes Engineering Challenge

What appears straightforward in concept—placing concrete on soil to create a structural floor—becomes extraordinarily complex when engineers must account for the myriad factors that influence real-world slab performance. Soil variability represents the primary challenge, as subgrade conditions rarely match the uniform properties assumed in simplified analyses, and changes in moisture content can dramatically alter soil stiffness and support characteristics.

Curling and warping effects introduce significant complications in ground-supported slab behavior, as differential moisture and temperature conditions between the top and bottom surfaces of the slab create internal stresses that can lead to cracking, corner lifting, and joint problems. These effects are particularly problematic in large slabs with wide joint spacing, where restraint from the subgrade can induce substantial tensile stresses.

Curling Stress from Temperature Differential = Function of Thermal Gradient

σ_curl = α × E × ΔT × t / (2 × (1-ν))

Where σ_curl is the curling stress, α is the thermal expansion coefficient, E is concrete modulus, ΔT is the temperature differential between top and bottom surfaces, t is slab thickness, and ν is Poisson's ratio. This relationship shows how even small temperature differences can generate significant stresses in restrained slabs.

Joint design presents another layer of complexity, as these intentional discontinuities must accommodate movement while maintaining load transfer and preventing water infiltration. The interaction between joint spacing, slab thickness, reinforcement placement, and anticipated movements requires careful analysis to prevent random cracking and ensure long-term performance.

Joint Spacing for Shrinkage Control = Function of Slab Thickness and Reinforcement

L_joint = 24 × t (unreinforced) to 36 × t (reinforced)

Where L_joint is the maximum joint spacing and t is the slab thickness. However, this simplified relationship must be modified for specific concrete properties, environmental conditions, and loading requirements, making joint design a complex engineering decision rather than a simple rule application.

Load transfer mechanisms add further complexity, as concentrated loads must be distributed through the slab to the subgrade without exceeding either the structural capacity of the concrete or the bearing capacity of the soil. The size and distribution of load contact areas, the presence of load transfer devices, and the stiffness characteristics of both slab and subgrade all influence how loads are carried and distributed.

While these complex interactions challenge traditional analysis methods, our XLC add-in displays all governing equations as easily readable mathematical expressions directly in Excel, transforming sophisticated slab-soil interaction calculations into manageable engineering analysis. The add-in's equation verification feature allows engineers to check their ground-supported slab calculations against established theory while maintaining the familiar Excel environment.

Professional Approach: Ensuring Ground-Supported Slab Performance

Professional ground-supported slab design demands comprehensive understanding of structural mechanics, soil engineering, and construction practices that extends far beyond cookbook approaches to thickness determination. The consequences of slab failure in industrial facilities can be catastrophic, involving not only structural damage but operational shutdowns that cost millions of dollars while repairs are completed.

Modern slab design practice emphasizes performance-based specifications that address not only structural adequacy but also serviceability requirements such as flatness, smoothness, and durability. Industrial facilities often require floor flatness tolerances measured in fractions of inches over substantial distances, demanding precision in both design and construction that challenges conventional practice.

The ExcelCalcs community shares a passion for making accurate ground-supported slab calculations with MS Excel, providing a platform where engineers can access expert knowledge through our comments feature and learn from the extensive experience of practitioners who have designed thousands of successful industrial floors. Our repository's worked solutions give engineers a head start in solving complex slab-soil interaction problems, building on existing Excel skills with a much faster learning curve than specialized finite element software.

Our GRDSLAB.xls calculation, expertly developed by Alex Tomanovich, provides not just the calculation methodology but also the documentation standards expected in professional practice. The comprehensive analysis includes checks for bending moments, shear forces, deflection limits, and crack control that engineers need for complete slab design verification.

Quality assurance in ground-supported slab design requires checking multiple performance criteria: structural capacity under design loads, deflection limits for equipment operation, crack control for durability, and joint performance for long-term serviceability. Each criterion requires different analysis approaches and acceptance limits, creating a comprehensive framework that addresses all aspects of slab performance.

Construction quality control becomes critical for ground-supported slabs, as variations in subgrade preparation, concrete placement, and curing can significantly impact final performance. Regular monitoring of subgrade conditions, concrete properties, and finishing operations helps ensure that the constructed slab matches design assumptions and performance expectations.

Repository Showcase: Comprehensive Ground-Supported Slab Solutions

The ExcelCalcs repository offers an extensive collection of ground-supported slab design tools to address various applications, loading conditions, and international standards. Beyond our flagship GRDSLAB.xls analysis, engineers can access specialized calculations including Slab on Grade Point Load Check (115 downloads, 4.2-star rating), Punching Shear Check - Concrete Slab (Rectangular and Circular) (229 downloads, 5.0-star rating), and Two-Way Slab Design to BS 8110 (272 downloads, 4.4-star rating).

For comprehensive slab design projects, our repository includes Design of RCC Rectangular Slabs as per IS 456-2000 for Indian standards (156 downloads, 4.4-star rating), Cantilever Slab Analysis & Design-ACI for American codes (148 downloads, 4.2-star rating), and DESIGN OF ONE-WAY RC SLAB ACCORDING TO CSA A23.3-14 for Canadian practice (132 downloads, 3.4-star rating). Advanced applications can utilize Flat Slab Analysis By Direct Method (192 downloads, 4.3-star rating), Slab Punching Design According ACI318-08 (153 downloads, 4.5-star rating), and Bridge Slab Design for specialized applications (197 downloads, 4.7-star rating). This diversity ensures that regardless of your project type, loading conditions, or local code requirements, our community has developed solutions to meet your ground-supported slab design needs.

Start Your Ground-Supported Slab Design Journey Today

Understanding ground-supported slab design principles represents a critical skill for any structural engineer working with industrial facilities, commercial buildings, or infrastructure projects requiring large-area floor systems. Our comprehensive GRDSLAB.xls calculation, developed by community contributor Alex Tomanovich, provides the tools you need to design efficient, reliable ground-supported slabs that won't experience the settlement problems that plagued the Minneapolis warehouse.

Visit our repository to download this essential calculation tool, which has been trusted by over 2,058 engineers worldwide. With its 4.6-star rating and proven track record, this template gives you the confidence that comes from building on established structural and geotechnical engineering principles. We extend our gratitude to Alex Tomanovich for sharing his expertise with the ExcelCalcs community—this exemplifies the collaborative spirit that makes our platform a valuable resource for engineers tackling complex slab-soil interaction challenges.

Take advantage of our professional subscription benefits, including access to our entire repository of calculation templates, the innovative XLC add-in that displays formulas as mathematical equations, and our active community of engineering professionals. At just $99 for a 12-month subscription—insignificant compared to specialized structural analysis software packages—you get the productivity gains that come from building on software you already know.

Students and teachers receive a 50% discount, making professional-grade ground-supported slab design tools accessible to the next generation of engineers. Free trials are available for both our repository downloads and the XLC add-in, allowing you to experience the difference quality tools make in your slab design practice.

Join the ExcelCalcs community today and discover why thousands of engineers trust our templates for their most critical ground-supported slab design challenges. Because when your foundation spans across challenging soils, you need calculations that provide solid support.